Sprackers

Enthusiast

- Messages

- 353

- Location

- Tunbridge Wells England

After much deliberation and reading of my last thread comments, I'm going to attempt to change my clutch plate.

I don't have a winch or even a big garage, but with a patience and guidance I reckon I can do it.

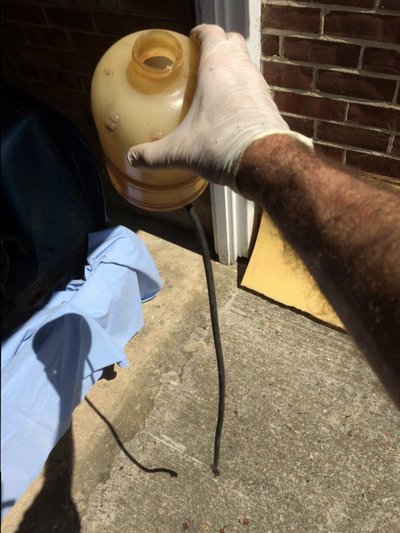

The clutch plate arrived and I also ordered 4 new tie rod ends and bottom things. (see Photo). these were told at the MOT needed changing.

First things first get Christine up off the floor on a permanent set of bricks, then drain the oil from both the gearbox and the engine.

Unless anyone has anything else to add I will be back soon with photos.

I now know how Jacques Cousteau felt as he prepared to dive into "ze ocean depths" (said in a French accent

)

)

Wish me luck

Sprackers.

I don't have a winch or even a big garage, but with a patience and guidance I reckon I can do it.

The clutch plate arrived and I also ordered 4 new tie rod ends and bottom things. (see Photo). these were told at the MOT needed changing.

First things first get Christine up off the floor on a permanent set of bricks, then drain the oil from both the gearbox and the engine.

Unless anyone has anything else to add I will be back soon with photos.

I now know how Jacques Cousteau felt as he prepared to dive into "ze ocean depths" (said in a French accent

)

)Wish me luck

Sprackers.