Vulgalour

Enthusiast

- Messages

- 198

- Location

- UK

Just a little job today. Went and picked this little lot up.

One of the rims needs attention. Going to give it a good going over with a power tool, paint the bit the tyre sits against and pass it back to them to get the fifth tyre fitted. Not mega important just yet.

Looks better for new tyres. Annoyingly, I have found that one back brake has now joined the party and stuck on so I only have one functioning rear drum now, the other three are all stuck on. I've not had chance to do anything about it.

I went for Kumho Solus tyres as they were middle of the road on price and ratings. Engineered in Korea is proudly printed on the label, though what that actually means is really anyone's guess. £7 per rim for fitting, balancing, new valves and disposal of the old tyres and inner tubes. Plus VAT.

Just waiting on the solder arriving so the air jet/emulsion tube can be repaired and we can see if that's fixed it. If it has, then super! If not, new carb time. Also still waiting on news from the supplier in the Netherlands that supposedly has the correct radiator. With the time it's taken I expect it'll be another not-in-stock result as it has with every other supplier. We'll get there, not much to do now and the days are getting longer so it's starting to get easier to get the time in on it.

One of the rims needs attention. Going to give it a good going over with a power tool, paint the bit the tyre sits against and pass it back to them to get the fifth tyre fitted. Not mega important just yet.

Looks better for new tyres. Annoyingly, I have found that one back brake has now joined the party and stuck on so I only have one functioning rear drum now, the other three are all stuck on. I've not had chance to do anything about it.

I went for Kumho Solus tyres as they were middle of the road on price and ratings. Engineered in Korea is proudly printed on the label, though what that actually means is really anyone's guess. £7 per rim for fitting, balancing, new valves and disposal of the old tyres and inner tubes. Plus VAT.

Just waiting on the solder arriving so the air jet/emulsion tube can be repaired and we can see if that's fixed it. If it has, then super! If not, new carb time. Also still waiting on news from the supplier in the Netherlands that supposedly has the correct radiator. With the time it's taken I expect it'll be another not-in-stock result as it has with every other supplier. We'll get there, not much to do now and the days are getting longer so it's starting to get easier to get the time in on it.

Here its just not the renault who need tlc but my east block MZ.

Here its just not the renault who need tlc but my east block MZ.

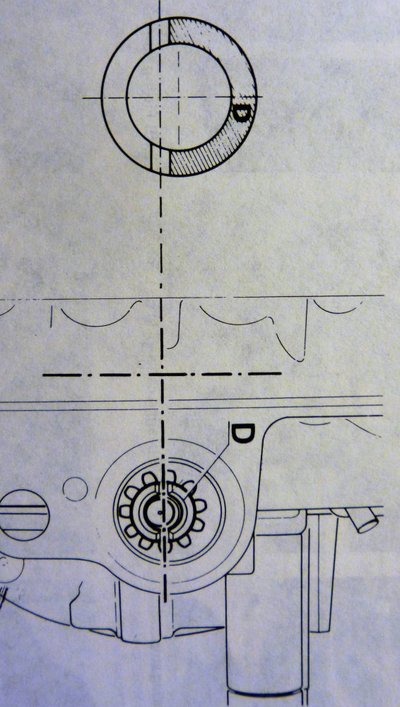

Seems likely at this point. I'm not entirely sure what I've misunderstood to have got the rotor arm in the wrong place as I thought I'd done it right and thought the valves were where they needed to be as things are in the above photographs. I wasn't going to worry about the rotor arm until I'd done the other steps before it.

Seems likely at this point. I'm not entirely sure what I've misunderstood to have got the rotor arm in the wrong place as I thought I'd done it right and thought the valves were where they needed to be as things are in the above photographs. I wasn't going to worry about the rotor arm until I'd done the other steps before it.