harbourseal

Renault R4 Lunatic

- Messages

- 1,045

- Location

- Breda The Netherlands

Hi All,

I started a new project today.

My F6 was struggling in France on the trip to Thenay. It turned out to have some compression issues on the third cilinder.

Since it is a 956 Renault 5 engine with 44 Hp it should not have been outrun bij an F4 with only 34 Hp.

We had an old 1108cc engine lying around that seemed to be stuck but was loose after all. I decided to use it for my F6. But it needs a complete rebuild.

Today I started to take it apart and clean some of the bits and pieces

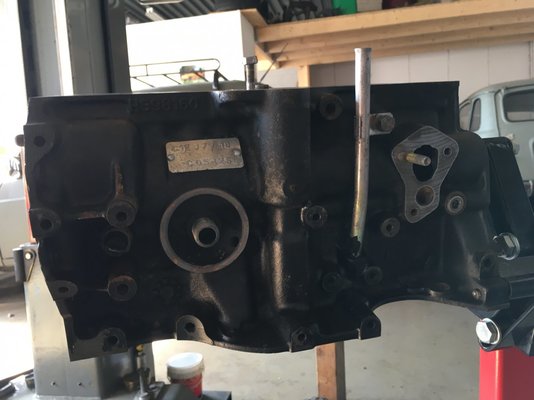

The engine as it was, dirty old and neglected. It came original from the GTL sinpar we rescued from a field.

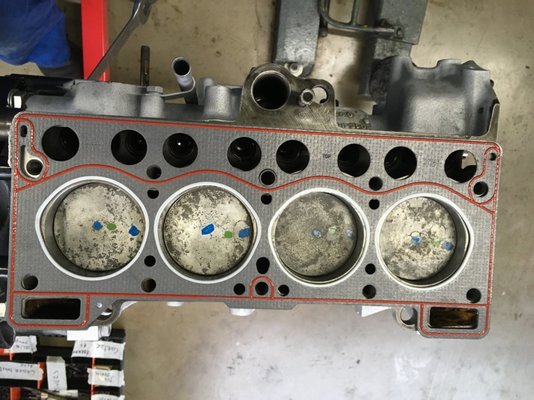

With the original head gasket. It doesn't look al that bad.

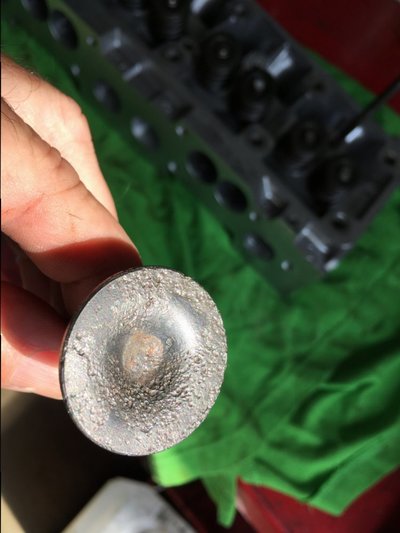

Cilinder one was the culprit for it seizing lots of rust.

All the other cilinders are filled with carbon flakes.

Carbon and rust in the head as well, but the valves have not eaten in to the seats. So quite good to use.

Nice clean up job.

Cilinder 1 looks like the previous owner used water as a coolant.

Inside the sump.

Oil pump already cleaned.

More parts are cleaned and in storage already until the new parts arrive.

Ill be taking the crankshaft and flywheel to a machineshop to have them balanced.

The head will be skimmed a bit for a little higher compression.

The engine block is going to have a bath to clean it up.

I started a new project today.

My F6 was struggling in France on the trip to Thenay. It turned out to have some compression issues on the third cilinder.

Since it is a 956 Renault 5 engine with 44 Hp it should not have been outrun bij an F4 with only 34 Hp.

We had an old 1108cc engine lying around that seemed to be stuck but was loose after all. I decided to use it for my F6. But it needs a complete rebuild.

Today I started to take it apart and clean some of the bits and pieces

The engine as it was, dirty old and neglected. It came original from the GTL sinpar we rescued from a field.

With the original head gasket. It doesn't look al that bad.

Cilinder one was the culprit for it seizing lots of rust.

All the other cilinders are filled with carbon flakes.

Carbon and rust in the head as well, but the valves have not eaten in to the seats. So quite good to use.

Nice clean up job.

Cilinder 1 looks like the previous owner used water as a coolant.

Inside the sump.

Oil pump already cleaned.

More parts are cleaned and in storage already until the new parts arrive.

Ill be taking the crankshaft and flywheel to a machineshop to have them balanced.

The head will be skimmed a bit for a little higher compression.

The engine block is going to have a bath to clean it up.