entwistlecymru

Enthusiast

- Messages

- 67

Seeing as I'm in the middle of converting my R4F6 to run a 5 speed box I thought I'd post pics to help anyone else thinking of doing the (hopefully worthwhile!) conversion.

First you need to find a 5 speed box. The cheapest route is to find a HA1 gearbox from a mk1 Renault 5. It's basically a HA0 box (the standard R4 gearbox) with an extra gear bolted on to the front of the casing and a different top cover for floor change (see below)

Because of the slightly longer casing there is some cutting and welding of the front crossmember needed so the bonnet will need to come off. If you can get hold of the donor cars X-member it may make things easier but I'll be making my own which should take up less space than welding on the 5's slightly chunky item.

Doing this conversion is a lot easier with the engine out - the standard box will need to come out anyway which means taking the engine out!

The first job is to convert the HA1 from floor change to dash change. Put both gearboxes into neutral to make rebuilding easier. You need to take the top of your HA0 box off (12 x 11mm bolts) and put to one side. Do the same with the HA1. Notice the 'box top is plastic on the HA1 (below right) and alloy in the HA0 (below left).

The next job is to swap the reverse gear selector arm which is slightly smaller on the HA1 (bottom right in above pic). The HA1 reverse selector is held on with a circlip and bolted on on the HA0. You need to use the HA0 bolt and spacing washers with the HA1 reverse selector lever.

Now comes the tricky bit! I found this bit easier with the gearbox at eye height (I put it on a stool on my worktop). You need to line up the gear lever and both ends of the reverse selector with the right bits in the gearbox. It's quite hard to explain but easy when you get around to it.

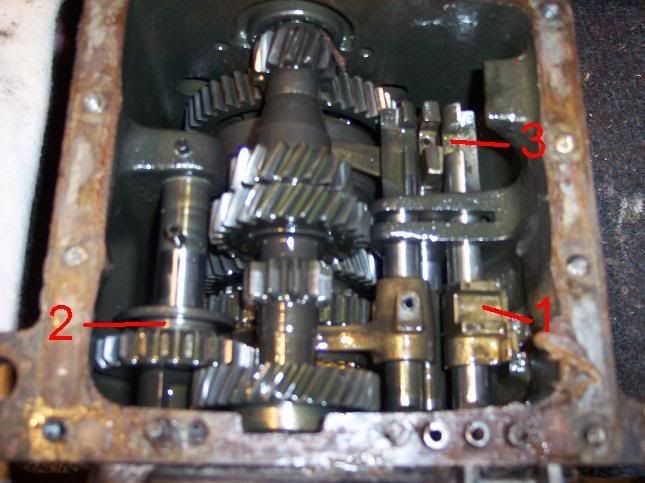

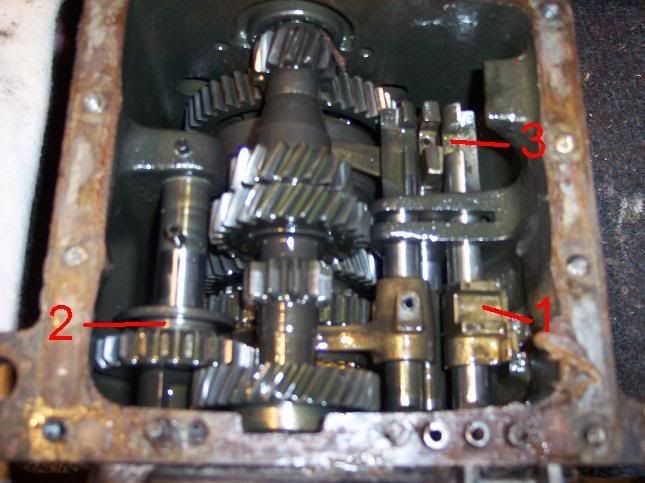

With the top of the box placed loosely down on the box, you can just see where the main selector and the reverse selector need to go.

The short fat arm of the reverse selector fits into slot marked 1.

The longer, thinner arm fits into the ring on the reverse cog marked 2.

The main selector needs to fit into the slot between the 3 selectors marked 3. The slots in the 3 selectors should be aligned if you put he box into neutral before starting!

Once all 3 selectors are lined up properly the top of the box can be bolted down. You may find if the top of the box has been off beofre that the gasket is a bit ropey. You can either cut a new one or do as I did and use silicon. Tighten all 12 bolts equally and try selecting all 6 gears.

The next installment will be the dirty job of cutting the old crossmember out and making a new one. Check back soon!

First you need to find a 5 speed box. The cheapest route is to find a HA1 gearbox from a mk1 Renault 5. It's basically a HA0 box (the standard R4 gearbox) with an extra gear bolted on to the front of the casing and a different top cover for floor change (see below)

Because of the slightly longer casing there is some cutting and welding of the front crossmember needed so the bonnet will need to come off. If you can get hold of the donor cars X-member it may make things easier but I'll be making my own which should take up less space than welding on the 5's slightly chunky item.

Doing this conversion is a lot easier with the engine out - the standard box will need to come out anyway which means taking the engine out!

The first job is to convert the HA1 from floor change to dash change. Put both gearboxes into neutral to make rebuilding easier. You need to take the top of your HA0 box off (12 x 11mm bolts) and put to one side. Do the same with the HA1. Notice the 'box top is plastic on the HA1 (below right) and alloy in the HA0 (below left).

The next job is to swap the reverse gear selector arm which is slightly smaller on the HA1 (bottom right in above pic). The HA1 reverse selector is held on with a circlip and bolted on on the HA0. You need to use the HA0 bolt and spacing washers with the HA1 reverse selector lever.

Now comes the tricky bit! I found this bit easier with the gearbox at eye height (I put it on a stool on my worktop). You need to line up the gear lever and both ends of the reverse selector with the right bits in the gearbox. It's quite hard to explain but easy when you get around to it.

With the top of the box placed loosely down on the box, you can just see where the main selector and the reverse selector need to go.

The short fat arm of the reverse selector fits into slot marked 1.

The longer, thinner arm fits into the ring on the reverse cog marked 2.

The main selector needs to fit into the slot between the 3 selectors marked 3. The slots in the 3 selectors should be aligned if you put he box into neutral before starting!

Once all 3 selectors are lined up properly the top of the box can be bolted down. You may find if the top of the box has been off beofre that the gasket is a bit ropey. You can either cut a new one or do as I did and use silicon. Tighten all 12 bolts equally and try selecting all 6 gears.

The next installment will be the dirty job of cutting the old crossmember out and making a new one. Check back soon!

)

)