Emanuel Botelho

Enthusiast

- Messages

- 7

- Location

- Portugal

Hello everyone! My 1991 GTL is half-project, half-daily driver, and one thing I'd like to finally address is the lack of the smaller plastic cladding bits behind the front wheel wells.

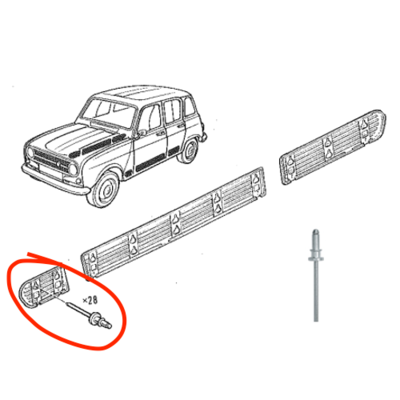

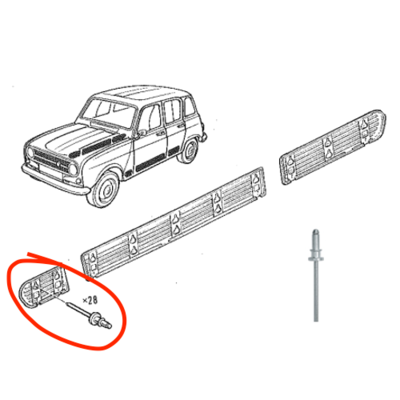

I have the plastic cladding. Have had it for way too long, and I want to finally get this done. How should I go about drilling the holes? I've seen online parts stores sell regular rivets for this (screenshot below) but I don't really understand the process, looking at the diagram; never used rivets before, and I've just started "wrenching" in the last couple of years, ever since I bought the Quatrelle. Any help/suggestions for this would be greatly appreciated! Cheers from Portugal!

I have the plastic cladding. Have had it for way too long, and I want to finally get this done. How should I go about drilling the holes? I've seen online parts stores sell regular rivets for this (screenshot below) but I don't really understand the process, looking at the diagram; never used rivets before, and I've just started "wrenching" in the last couple of years, ever since I bought the Quatrelle. Any help/suggestions for this would be greatly appreciated! Cheers from Portugal!