Q plate

Enthusiast

- Messages

- 58

- Location

- Birmingham/ Cwmbran

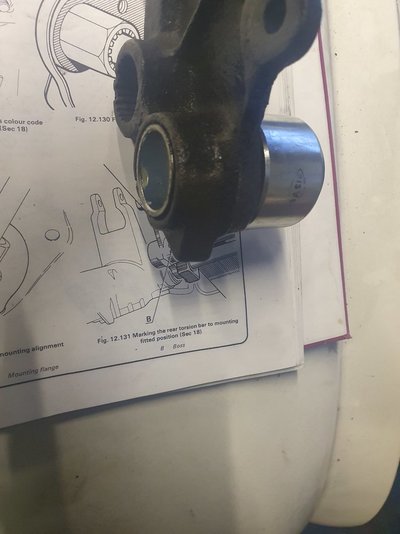

Seasons greetings all I've read extensively about removing the rear bars made a start this afternoon no progress so far gonna have a tidy up and leave them to soak again but just wondered is there an actual stop on these ie I've been striking it from both ends trying to get it to move when it dawned on me that could be a waste of time.. for info Im intending to refurb the back axle/replace silent blocks etc.. thanks in advance