I have a left hand drive R1128 GTL first registered in December 1981. I recently took the engine and gearbox out to have the flywheel refaced and to replace the clutch. I also replaced all the suspension and steering rack ball joints.

When refitting the offside drive shaft I must have forced the CV end a bit to much because when I looked at the installed shaft, the large end of the gaiter had popped off the hub. I cleaned the old grease out and repacked the gaiter with new CV grease. After many attempts, I managed to get the very tight clip over the large diameter end of the gaiter. It aligned well but there was grease over everything!

I started the car on stands put it in gear and let the hubs turn a few times. When I checked it out I saw that the gaiter had become very twisted such that the large end was ready to pop off again!

That surprised me since I reasoned that the hub and the shaft would each turn at the same rate.

Can anyone help me understand what is happening to make it twist or let me know if I have done something wrong or omitted a step in what I did?

Thanks,

Johnny

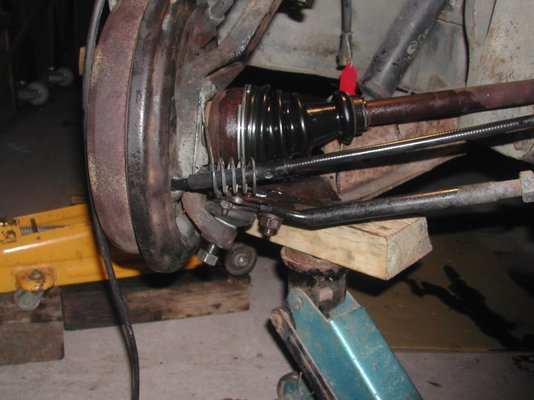

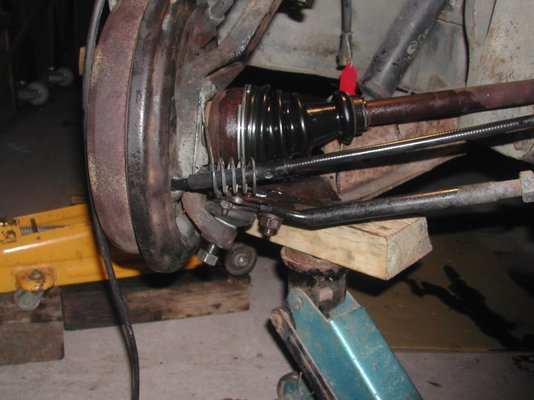

I took a snap or two!

When refitting the offside drive shaft I must have forced the CV end a bit to much because when I looked at the installed shaft, the large end of the gaiter had popped off the hub. I cleaned the old grease out and repacked the gaiter with new CV grease. After many attempts, I managed to get the very tight clip over the large diameter end of the gaiter. It aligned well but there was grease over everything!

I started the car on stands put it in gear and let the hubs turn a few times. When I checked it out I saw that the gaiter had become very twisted such that the large end was ready to pop off again!

That surprised me since I reasoned that the hub and the shaft would each turn at the same rate.

Can anyone help me understand what is happening to make it twist or let me know if I have done something wrong or omitted a step in what I did?

Thanks,

Johnny

I took a snap or two!