Hi,

Remember the water leak that I suspected to be the flush screw?

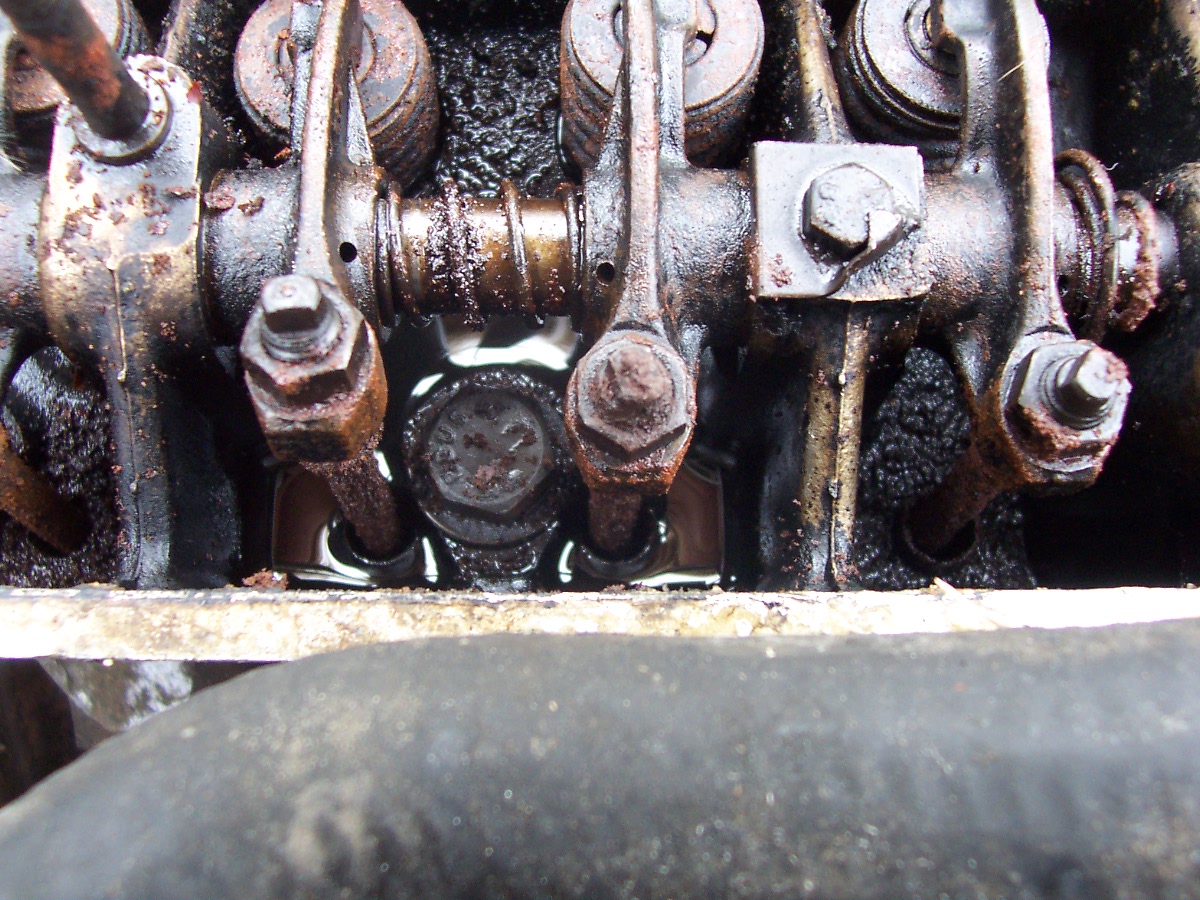

Well it's much worse....the engine block is cracked ! I managed to slip the digi camera way below the manifold and look what it revealed !(see photo)

Nasty ! I was thinking that I might try to seal this 12 cm crack with metal cement puty...do you guys think it might hold ?

Another solution would be argon font welding, but the spot is very inaccesible.

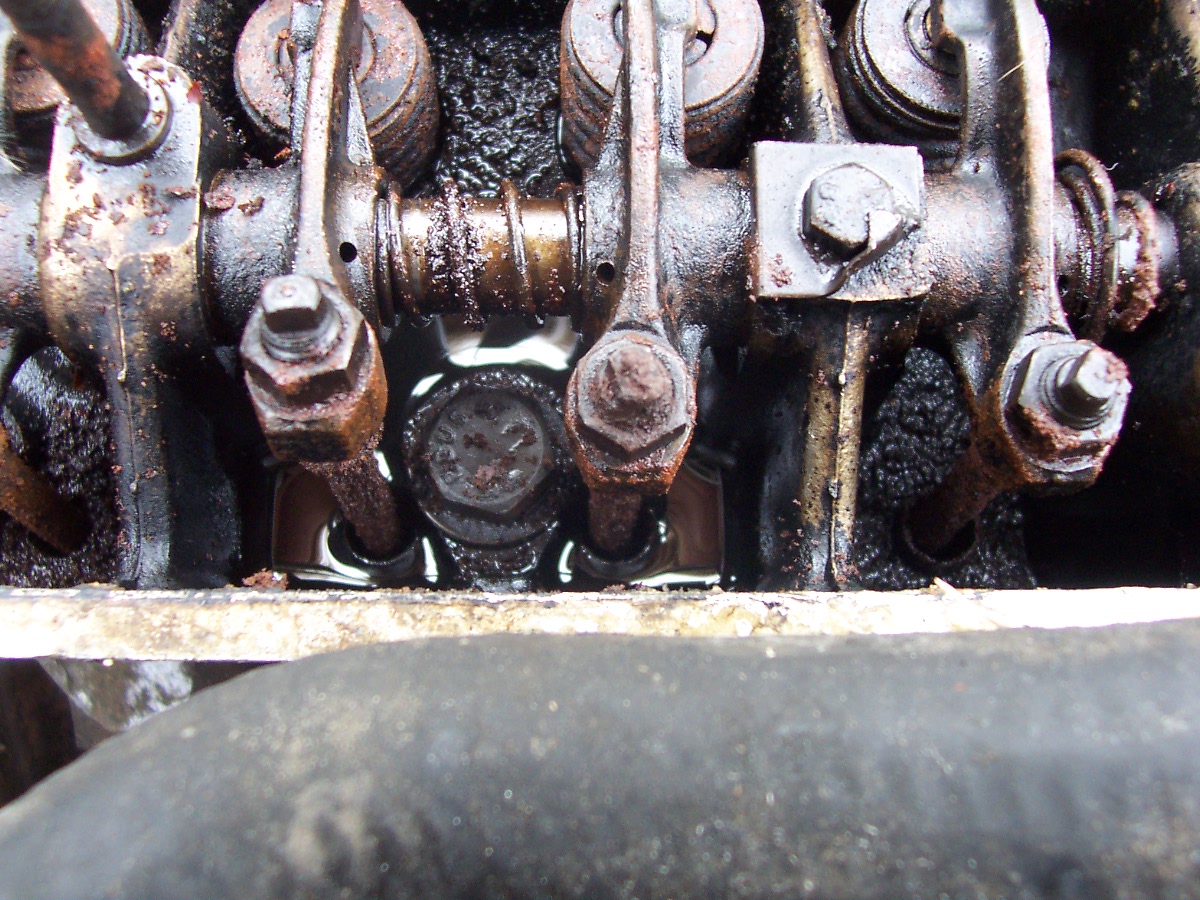

Furthermore, considering the rust that has formed on the pushrods and the rocker arms, (see photo)I wonder if water has mixed with oil or do you think this rust is due to the fact that the engine was abandonned for 5 years.

I would need some advice.

Thanks

By the way, since I am talking about my 4L (safari 1978) I haven't had the oportunity to show it, well here it is

Remember the water leak that I suspected to be the flush screw?

Well it's much worse....the engine block is cracked ! I managed to slip the digi camera way below the manifold and look what it revealed !(see photo)

Nasty ! I was thinking that I might try to seal this 12 cm crack with metal cement puty...do you guys think it might hold ?

Another solution would be argon font welding, but the spot is very inaccesible.

Furthermore, considering the rust that has formed on the pushrods and the rocker arms, (see photo)I wonder if water has mixed with oil or do you think this rust is due to the fact that the engine was abandonned for 5 years.

I would need some advice.

Thanks

By the way, since I am talking about my 4L (safari 1978) I haven't had the oportunity to show it, well here it is

Last edited by a moderator: