Billancourt

Enthusiast

- Messages

- 57

- Location

- London

Hi All

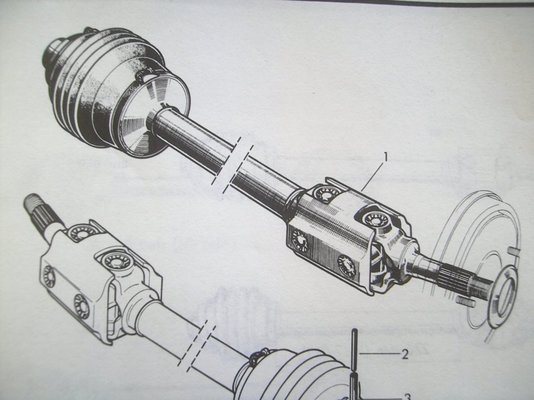

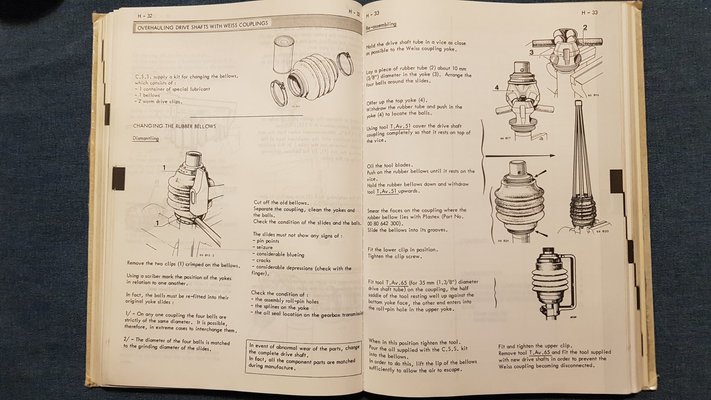

I was wondering if it is possible to change the inner driveshaft gaiter on an early driveshaft. The Haynes manual suggests it is possible to repair but advises that it is a job for a Renault dealership (special tool required?) I was wondering if anyone on the forum has tackled this job themselves. Any advise would be gratefully received. Please see image of type of driveshaft below.

I was wondering if it is possible to change the inner driveshaft gaiter on an early driveshaft. The Haynes manual suggests it is possible to repair but advises that it is a job for a Renault dealership (special tool required?) I was wondering if anyone on the forum has tackled this job themselves. Any advise would be gratefully received. Please see image of type of driveshaft below.