malcolm

& Clementine the Cat

- Messages

- 4,637

- Location

- Bedford UK

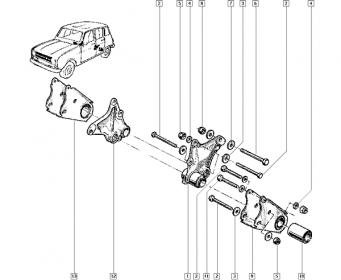

I've bought a set of front suspension bushes that includes the lower arm inner bush. It's metal sleeved inside and out, but there doesn't appear to be access to press out the bush by the outer sleeve. Has anyone replaced this bush?

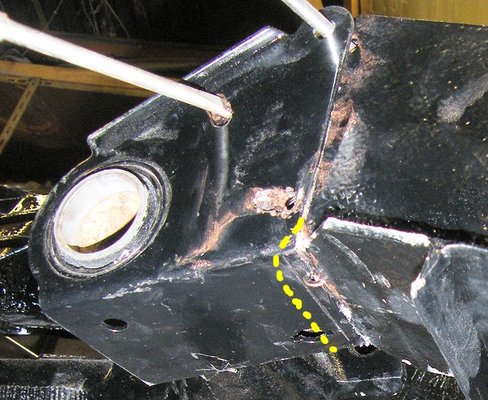

Onto the rear suspension. My manuals are rubbish for later cars (hence this post). Really ought to seek out a factory manual that covers the GTL. Does anyone know what type of bush holds the suspension mounting to the inner mounting (arrowed in the photo)? I have a new outer mounting and I'm tempted to replace the inner mounting while I'm at it (but first more struggling with the torsion bars).

Onto the rear suspension. My manuals are rubbish for later cars (hence this post). Really ought to seek out a factory manual that covers the GTL. Does anyone know what type of bush holds the suspension mounting to the inner mounting (arrowed in the photo)? I have a new outer mounting and I'm tempted to replace the inner mounting while I'm at it (but first more struggling with the torsion bars).