You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Front brake cylinders

- Thread starter jonigel

- Start date

Hello Angel

Thanks for the reply,i would be interested in buying a left hand one ,how much?

Unfortunately you cannot get the later cylinder on a 180 backplate,it just wont work.

Had i realised how difficult this has turned out i would have gone the French way and changed the whole lot to the later model, c,est la vie.

You can e-mail me on jonigel@myway.com.

Thanks for the reply,i would be interested in buying a left hand one ,how much?

Unfortunately you cannot get the later cylinder on a 180 backplate,it just wont work.

Had i realised how difficult this has turned out i would have gone the French way and changed the whole lot to the later model, c,est la vie.

You can e-mail me on jonigel@myway.com.

Geoff in the Gully

Getting it together

- Messages

- 283

- Location

- Upper Ferntree Gully, Victoria, Australia

I wasn't able to make the longer wheel cylinder fit. I thought I might be able to trim the brake shoe to fit. That would have worked except there was a hole the shoes just where I needed to cut to and that meant there would be no metal to press up against the piston in the wheel cylinder.

I'm looking into reducing the wheel cylinder on a lathe or getting an old one sleeved with a stainless steel insert. I'll let you know how they work out.

Geoff

I'm looking into reducing the wheel cylinder on a lathe or getting an old one sleeved with a stainless steel insert. I'll let you know how they work out.

Geoff

angel

Enthusiast

- Messages

- 2,562

- Location

- Athens, Greece

I have some news on this one...

Yesterday I had some time, and converted a long wheel cylinder in a short one, on the lathe.

It was relatively easy and the final result has no difference to the original short cylinder as the basic casting is the same in both cases. No honing or sleeving nesessary as the cylinder bore is not touched.

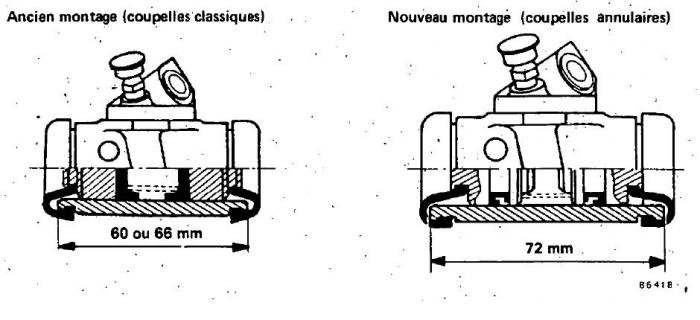

Piston and seal design differs between the two cylinders. The long one has an annular seal located further outwards and different piston design, as seen on the drawing.

I mounted the wheel cylinder on a 200 mm backplate, fitted a pair of brake shoes and turned the adjusters to their outermost position. Even after this, the pistons were flush with the outer edge of the cylinder body. So the piston will still work on a safe area, even on the large brake bacplate and there is no need to machine the piston to accept old style cup seals.

I need to do one more check to ensure the pistons will not need machining. This is to check whether there is enough distance between the pistons when the cylinder is mounted on a 180mm backplate and the shoes are adjusted to their innermost position.

As I don't have such a backplate on hand, would any fellow 4L-maniac with a spare 180mm backplate measure this for me? (Geoff in the Gully, jonigel or Malcolm?) I need the distance between the two points of the shoes that contact the pistons with the adjusters turned fully in. No need to fit the wheel cylinder, springs or handbrake mechanism.

Yesterday I had some time, and converted a long wheel cylinder in a short one, on the lathe.

It was relatively easy and the final result has no difference to the original short cylinder as the basic casting is the same in both cases. No honing or sleeving nesessary as the cylinder bore is not touched.

Piston and seal design differs between the two cylinders. The long one has an annular seal located further outwards and different piston design, as seen on the drawing.

I mounted the wheel cylinder on a 200 mm backplate, fitted a pair of brake shoes and turned the adjusters to their outermost position. Even after this, the pistons were flush with the outer edge of the cylinder body. So the piston will still work on a safe area, even on the large brake bacplate and there is no need to machine the piston to accept old style cup seals.

I need to do one more check to ensure the pistons will not need machining. This is to check whether there is enough distance between the pistons when the cylinder is mounted on a 180mm backplate and the shoes are adjusted to their innermost position.

As I don't have such a backplate on hand, would any fellow 4L-maniac with a spare 180mm backplate measure this for me? (Geoff in the Gully, jonigel or Malcolm?) I need the distance between the two points of the shoes that contact the pistons with the adjusters turned fully in. No need to fit the wheel cylinder, springs or handbrake mechanism.

Geoff in the Gully

Getting it together

- Messages

- 283

- Location

- Upper Ferntree Gully, Victoria, Australia

I've had a look at my 180mm backplates. They've got jammed adjusters and I didn't have time to free them so I have done some estimating to calculate where the shoes would be with them backed right off. I reckon the distance between the points on the shoes that test on the cylinder pistons are 50mm apart when fully backed off. Give or take a few mm.

My news on this topic is that I've had a look at my brother's Dauphine's wheel cylinders.

They are short also - 60mm. The rear cylinders also physically fit in the backing plate.

The rear cylinders have an angled brake line entry (you might need to put them on the 'other' side to get them to point the right way but that wouldn't be a problem). However, the Dauphine rear cylinders are only 19mm diameter.

I haven't got hold of a front wheel cylinder to compare yet. But they are 22 mm - a bit smaller than the R4 23-something size, but maybe close enough to not worry too much.

The good part of this is that Melun Retro Passion have them for 36 Euro rather than the 127 for a pair of R4 ones. Franzose have some also for Dauphine but they quote a different diameter.

Geoff

My news on this topic is that I've had a look at my brother's Dauphine's wheel cylinders.

They are short also - 60mm. The rear cylinders also physically fit in the backing plate.

The rear cylinders have an angled brake line entry (you might need to put them on the 'other' side to get them to point the right way but that wouldn't be a problem). However, the Dauphine rear cylinders are only 19mm diameter.

I haven't got hold of a front wheel cylinder to compare yet. But they are 22 mm - a bit smaller than the R4 23-something size, but maybe close enough to not worry too much.

The good part of this is that Melun Retro Passion have them for 36 Euro rather than the 127 for a pair of R4 ones. Franzose have some also for Dauphine but they quote a different diameter.

Geoff

angel

Enthusiast

- Messages

- 2,562

- Location

- Athens, Greece

Thank you Geoff. The two humps on the back side of the pistons will need some millimeters to be machined off.Just a precaution, as their outer faces are exactly 50mm apart when they are touching each other.

So for anyone interested I can supply right hand short wheel cylinders too. Price is 48,00 euros plus postage, this includes a new seal kit fitted.

So for anyone interested I can supply right hand short wheel cylinders too. Price is 48,00 euros plus postage, this includes a new seal kit fitted.

Geoff in the Gully

Getting it together

- Messages

- 283

- Location

- Upper Ferntree Gully, Victoria, Australia

An update on this topic . . .

Rear wheel cylinders from a Renault R12 are almost the same as the front wheel cylinders of an early R4. They fit the backing plate, are 60mm long, have angled brake hose entry. Same size mounting bolts. Only difference I found was the R12 cylinders are 22 mm diameter instead of the 23.8 of the R4.

When we redid the brakes on my daughter's '70 R12 we put in new rear wheel cylinders - they were easily available locally and less than the price of getting a seal kit imported. Which is a whole lot easier than finding the 60mm front cylinders for my R4.

I guess the 22mm would make the brakes a bit heavier, but as an option when none others are available I think this is worth remembering.

And on a related note, the rear backing plates from a Dauphine are the same as the front backing plates of an early R4. Surprising what you find out when everyone dumps their parts on your bench - my brothers doing up a Dauphine.

Geoff

Rear wheel cylinders from a Renault R12 are almost the same as the front wheel cylinders of an early R4. They fit the backing plate, are 60mm long, have angled brake hose entry. Same size mounting bolts. Only difference I found was the R12 cylinders are 22 mm diameter instead of the 23.8 of the R4.

When we redid the brakes on my daughter's '70 R12 we put in new rear wheel cylinders - they were easily available locally and less than the price of getting a seal kit imported. Which is a whole lot easier than finding the 60mm front cylinders for my R4.

I guess the 22mm would make the brakes a bit heavier, but as an option when none others are available I think this is worth remembering.

And on a related note, the rear backing plates from a Dauphine are the same as the front backing plates of an early R4. Surprising what you find out when everyone dumps their parts on your bench - my brothers doing up a Dauphine.

Geoff