kevinandkate

Sadly no longer an owner

- Messages

- 138

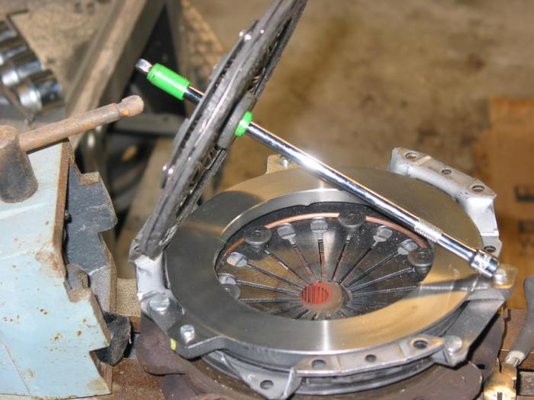

I am on with the delightful task of changing the clutch and have come to the point where the tubular crossmember needs to be removed. The first bolt sheared off which in itself is not a problem but the remains of the bolt cannot be abstracted as the end of the torsion bar is in the way. This appears to be the case with the remaining 3 bolts which are equally tight and likely to shear off. Even if they hadn't sheared I would be unable to remove the crossmemebr as the bolts would still be in situ-------- Help!!!. Any advice would be appreciated, at the moment it would seem the whole hub assembly and tortion bar will have to come off which I do not fancy doing if there is an alternative.