You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Timing chain adjusting

- Thread starter RAMI54

- Start date

The_Blacksmith

Enthusiast

- Messages

- 90

Do you have the engine type for me or the year the vehicle was built?

do you have the engine type for me or the year the vehicle was built?

the year the vehicle was built is 1982

angel

Enthusiast

- Messages

- 2,447

- Location

- Athens, Greece

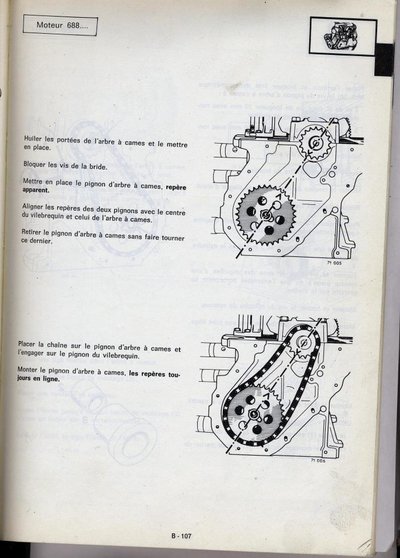

There is one dot on the crankshaft sprocket and another on the camshaft one. These should be away from each other (cramk towards the bottom, cam towards the top) and aligned in such a way that they form an imaginary line with the crankshaft and camshaft centers. If you get a manual you will see this in picture.

The_Blacksmith

Enthusiast

- Messages

- 90

The_Blacksmith

Enthusiast

- Messages

- 90

There is one dot on the crankshaft sprocket and another on the camshaft one. These should be away from each other (cramk towards the bottom, cam towards the top) and aligned in such a way that they form an imaginary line with the crankshaft and camshaft centers. If you get a manual you will see this in picture.

That would be for the 680 engine. I suspect this GTL has a 688 engine. But the principle is exactly the same.

That would be for the 680 engine. I suspect this GTL has a 688 engine. But the principle is exactly the same.

THANKS ALOT

The_Blacksmith

Enthusiast

- Messages

- 90

Let us know how it worked out.

let us know how it worked out.

no problem

let us know how it worked out.

this the way how it work .

By the way what is agood compression in this engine ?

Steve Hennessey

Moderator

- Messages

- 1,406

Can I suggest that you remove the tensioner and the first main bearing cap and check that the oilway drilling to the tensioner is free from any burnt carbon and sludge. Use a flexible brush and some degreaser and then blow it through with an air line. Clean up the tensioner as well - even better, fit a new one if you are also fitting a new chain.

can i suggest that you remove the tensioner and the first main bearing cap and check that the oilway drilling to the tensioner is free from any burnt carbon and sludge. Use a flexible brush and some degreaser and then blow it through with an air line. Clean up the tensioner as well - even better, fit a new one if you are also fitting a new chain.

the tensioner was remove and clean

The_Blacksmith

Enthusiast

- Messages

- 90

this the way how it work .

By the way what is agood compression in this engine ?

According to the Moteur C workshop manual 8,3.

according to the moteur c workshop manual 8,3.

can you please explain what do you mean ?

I HAVE ANOTHER QUESTION :

AFTER REBUILDIND THE ENGINE IS THEIR ANY ADDITIONAL WATER SOLUTION THAT NEEDS TO BE ADD TO THE COOLING SYSTEM IN ORDER TO PREVENT ANY LEAK OF WATER AND COMPRESSION AROUND THE SLIVES?

(SORRY ABOUT MY BAD ENGLISH)

angel

Enthusiast

- Messages

- 2,447

- Location

- Athens, Greece

That would be for the 680 engine. I suspect this GTL has a 688 engine. But the principle is exactly the same.

You are right...

About compression pressures, I cannot find any value stated, and I would be interested to know about them.

No additive other than glycol based coolant should be needed, Rami54. If, after removing the liners, their machined shoulders on the block are perfectly clean and flat, and the protrusion above the top of the block is carefully adjusted, they will not leak. Don't hurry on any of these.

you are right...

About compression pressures, i cannot find any value stated, and i would be interested to know about them.

No additive other than glycol based coolant should be needed, rami54. If, after removing the liners, their machined shoulders on the block are perfectly clean and flat, and the protrusion above the top of the block is carefully adjusted, they will not leak. Don't hurry on any of these.

thanks to all of you , today after noon i will work again in this engine HERE IS THE RETURNING THE SLIVES BACK

Steve Hennessey

Moderator

- Messages

- 1,406

Have you used new paper gaskets on the base of the liners?

have you used new paper gaskets on the base of the liners?

yes i do. Do i have to put silecon in the base of the liners?

Steve Hennessey

Moderator

- Messages

- 1,406

That's debatable. In the factory they did not use any silicon. The surfaces at the base of the liner and the machined groove in the block only required the paper gasket. If your surfaces are in perfect order (I assumed you cleaned them thoroughly) then the paper gasket will be ok. If you have any doubt then a thin smear of silicon gasket compound would not do any harm.