harbourseal

Renault R4 Lunatic

- Messages

- 1,045

- Location

- Breda The Netherlands

Good morning,

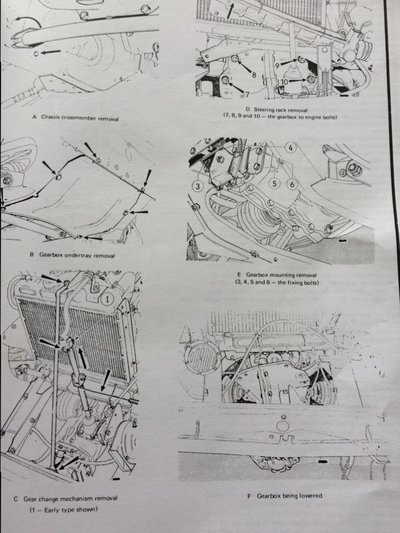

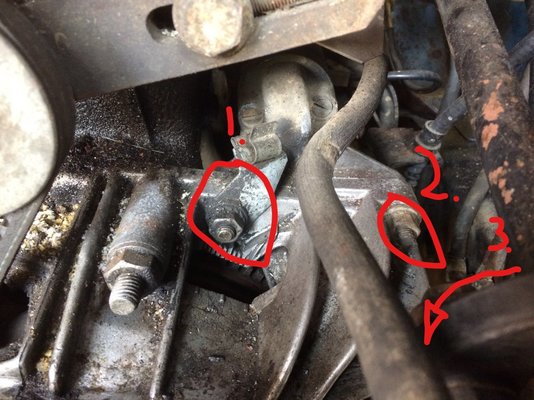

You have to undo the bolts that are more towards the engine. With what you have done now you have undone the bell house from the gearbox. The photo of mojo baby's gearbox is a 845cc gearbox. The bell housing is incorporated in the engine.

With your cleon 1108cc engine the bell housing is separate

Undo all the belts at the font of the engine and take the poulies of too, then you have access to all the bolts that hold the bell housing to the engine

But first put the bolts you have undone back in.

This afternoon I'll send you a picture where to find all the other bolts that hold the gearbox to the engine.

You have to undo the bolts that are more towards the engine. With what you have done now you have undone the bell house from the gearbox. The photo of mojo baby's gearbox is a 845cc gearbox. The bell housing is incorporated in the engine.

With your cleon 1108cc engine the bell housing is separate

Undo all the belts at the font of the engine and take the poulies of too, then you have access to all the bolts that hold the bell housing to the engine

But first put the bolts you have undone back in.

This afternoon I'll send you a picture where to find all the other bolts that hold the gearbox to the engine.

![IMG_4837[1].JPG IMG_4837[1].JPG](https://www.renault4.co.uk/forum/data/attachments/17/17019-a133c0744393c8688d1717c42d585127.jpg)

![IMG_4838[1].JPG IMG_4838[1].JPG](https://www.renault4.co.uk/forum/data/attachments/17/17020-98777d1c31a89a05d7fb585c5bda3f3c.jpg)

![IMG_4839[1].JPG IMG_4839[1].JPG](https://www.renault4.co.uk/forum/data/attachments/17/17021-9a44df941c27db751aff6880caa4b356.jpg)

![IMG_4840[1].JPG IMG_4840[1].JPG](https://www.renault4.co.uk/forum/data/attachments/17/17022-99d789251825ba3d8791f059e38dba1c.jpg)

![IMG_4842[1].JPG IMG_4842[1].JPG](https://www.renault4.co.uk/forum/data/attachments/17/17023-6a8a3c5016d17aaa5f9d3dbf87a435a1.jpg)

![IMG_4843[1].JPG IMG_4843[1].JPG](https://www.renault4.co.uk/forum/data/attachments/17/17024-2c0cbbf12668c6e0e1782f2199346d0c.jpg)

![IMG_4845[1].JPG](/forum/data/attachments/17/17025-97e3047c56c2e12478c9e86e1c0636f4.jpg)

![IMG_4846[1].JPG](/forum/data/attachments/17/17026-f597f6d014a8da385f1230f3cf2a75d5.jpg)