You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

look what I found

- Thread starter mojobaby

- Start date

mojobaby

Enthusiast

- Messages

- 1,288

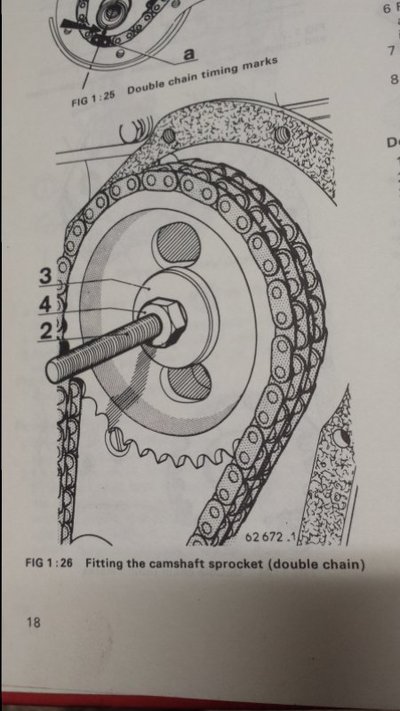

You are right Azazello! The most important factor is that the inside diameter of the washer is greater than the CENTRE ridge of the camshaft. It should also be a thick washer and higher than the centre. In that way the washer will ensure that the outer edge of the camshaft is level with the sprocket inner edge.

Thank you for your correction!

Thank you for your correction!

mr-reno-139

AKA Paul Cunningham

- Messages

- 2,247

- Location

- lancing west sussex england

You can have my opinion but I'm not sure I can offer a valid one seem to remember I've only done this job once and if you push the cam sprocket all the way on the FreePlay which is necessary for the camshaft to revolve freely disappears and then it will make resistance and possibly bind up and seize

If it is not pushed on far enough the camshaft is free to move backwards and forward which will upset things I guess seem to remember you were supposed to put a feeler gauge in somewhere to set the gap I will see if I have still got a genuine workshop manual somewhere

If it is not pushed on far enough the camshaft is free to move backwards and forward which will upset things I guess seem to remember you were supposed to put a feeler gauge in somewhere to set the gap I will see if I have still got a genuine workshop manual somewhere

mr-reno-139

AKA Paul Cunningham

- Messages

- 2,247

- Location

- lancing west sussex england

Sorry the only workshop manual I've got to hand here it's from 1963 when they had timing gears not chain lol

mojobaby

Enthusiast

- Messages

- 1,288

Been thinking about this for a couple of days and there are 2 ways to put the sprocket on the end of the camshaft.

Firstly the manuals above suggest that the end of the cam should be level with the flat surface of the sprocket.

The Heynes manual also says that the end float should be between 0,06 and 0,14mm.

But what if its an after market sprocket and slightly thicker (or thinner) than the original Renault sprocket. The end of the cam might be level with the sprocket on the outside but the inner measurement (end float) will be affected.

That is why when I rechecked it today, I made sure that the end float was 0,10mm (in the middle). The feeler gauge goes between the back of the sprocket and an oval plate that holds the camshaft in place.

It's a bit difficult to see on the photo.i have the feeler gauge in place. I'm quite happy with the result and thanks Azazello for noticing my mistake.

Firstly the manuals above suggest that the end of the cam should be level with the flat surface of the sprocket.

The Heynes manual also says that the end float should be between 0,06 and 0,14mm.

But what if its an after market sprocket and slightly thicker (or thinner) than the original Renault sprocket. The end of the cam might be level with the sprocket on the outside but the inner measurement (end float) will be affected.

That is why when I rechecked it today, I made sure that the end float was 0,10mm (in the middle). The feeler gauge goes between the back of the sprocket and an oval plate that holds the camshaft in place.

It's a bit difficult to see on the photo.i have the feeler gauge in place. I'm quite happy with the result and thanks Azazello for noticing my mistake.

Azazello

habitué

- Messages

- 1,109

- Location

- Italy

If the feeler reads 0,10 then it's good, and I see no mistakes!

We are very lucky proceeding with the same work together (I think there are 5 restorations going on contemporarily on this forum), each one experience can save the others a lot of hassle...

We are very lucky proceeding with the same work together (I think there are 5 restorations going on contemporarily on this forum), each one experience can save the others a lot of hassle...

mojobaby

Enthusiast

- Messages

- 1,288

Here is the reason why I haven't been working on my engine. The oil seal on the front plate of the gearbox.

The Renault part number is 77 03 087 086. I only discovered that its no longer available at Renault after I took it out. I searched local shops and the internet for 3 weeks. Then came Mr Reno to the rescue. He had one in his secret stash of spare parts and that took 2 weeks in the post to get to me. (thanks for your help and advice)

The old seal was a little different I think, and had a thin brass coloured ring to keep the seal in place. See photo. I'm not too sure whether I should put the ring back again. It's been damaged during removal but I can fix it. It's also not shown on my parts diagram 1104 that Tomcat sent me.

The Renault part number is 77 03 087 086. I only discovered that its no longer available at Renault after I took it out. I searched local shops and the internet for 3 weeks. Then came Mr Reno to the rescue. He had one in his secret stash of spare parts and that took 2 weeks in the post to get to me. (thanks for your help and advice)

The old seal was a little different I think, and had a thin brass coloured ring to keep the seal in place. See photo. I'm not too sure whether I should put the ring back again. It's been damaged during removal but I can fix it. It's also not shown on my parts diagram 1104 that Tomcat sent me.

mojobaby

Enthusiast

- Messages

- 1,288

the oil seal is finally in place. There's a small spring around the neck of the seal. I removed it to prevent damage, while I tapped the seal in using a socket. I had to lubricate the seal to get it in.

The plate was fitted to the gear box with a paper seal after first taping over the splines on the shaft to stop damage to the oil seal.

Then the clutch lever and thrust bearing were attached.

All lined up with copper grease on the spines

Fitted perfectly together and torqued the 10mm bolts to 29 ft/lbs

The plate was fitted to the gear box with a paper seal after first taping over the splines on the shaft to stop damage to the oil seal.

Then the clutch lever and thrust bearing were attached.

All lined up with copper grease on the spines

Fitted perfectly together and torqued the 10mm bolts to 29 ft/lbs

I remember I was buying standard seals at local store and had no problems finding the right size.(they were more flat than yours giving the shaft less movement to the sides ) But in my gearbox I didnt unscrew the plate. The seal came out from the outside and I put the seal back the same way. Actually I bought two seals and put two inside

.

.

mr-reno-139

AKA Paul Cunningham

- Messages

- 2,247

- Location

- lancing west sussex england

Well done

Hope you've got a yellow fan blade to bolt on as well

Going back to oil seals for a moment if I rember rightly the reason for the unique design of the part I sent you is because although seal is available easily that size the seal itself is offset

Pretty sure a standard seal won't fit on the raised section on primary gearbox correctly

My last research was 25 years back so I may be wrong

Hope you've got a yellow fan blade to bolt on as well

Going back to oil seals for a moment if I rember rightly the reason for the unique design of the part I sent you is because although seal is available easily that size the seal itself is offset

Pretty sure a standard seal won't fit on the raised section on primary gearbox correctly

My last research was 25 years back so I may be wrong

harbourseal

Renault R4 Lunatic

- Messages

- 1,045

- Location

- Breda The Netherlands

Well done. Mine will be going into a paint booth in 2 weeks time. I heard the roar 2 months ago. It will be music to your ears.

Good luck.

Robert

Good luck.

Robert

mojobaby

Enthusiast

- Messages

- 1,288

Mr Reno, you may be correct because when I searched the internet for an oil seal 17x29x7, the results look nothing like the seal that you sent to me. There's another one in the gearbox as well. They look identical, but the size is 17x28x7.

Maybe that's why Chudson put 2 seals in his front plate?

I'm just very glad that you found it for me.

No yellow fan for me, but a red one briefly crossed my mind.

Maybe that's why Chudson put 2 seals in his front plate?

I'm just very glad that you found it for me.

No yellow fan for me, but a red one briefly crossed my mind.

mr-reno-139

AKA Paul Cunningham

- Messages

- 2,247

- Location

- lancing west sussex england

Pretty sure the difference were to do with the clutch release bearing type as early coils spring clutches had no guide tube for release bearing

Then again it could be 334 boxes all had different types or the 354 gtl box used a different seal as it revolves different ways and some seals are handed and using different size stoppedto dtop accidental wrong fitting

Then again it could be 334 boxes all had different types or the 354 gtl box used a different seal as it revolves different ways and some seals are handed and using different size stoppedto dtop accidental wrong fitting

My biggest moment and I blurred it.

My biggest moment and I blurred it.