Yeah I totally agree, better change it while I'm at it. And keep it up with the clichés, they are quite amusing!

A summary of what I am planning to do next:

- Get the manifold off of the head, check for leaks, find a shop to refurbish the head and tune the rockers

- Flush the block and the sump with Diesel to remove some of the sludge

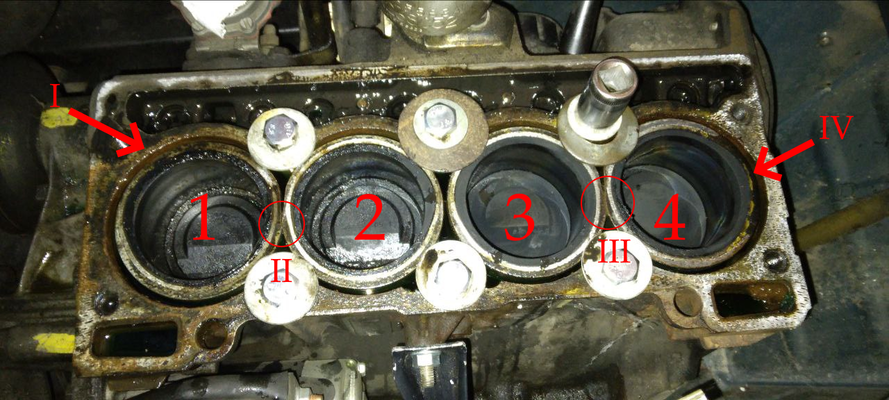

- Clean the mating surfaces of the liners

- Hose down the cooling system to remove as much debris as possible while I'm at it

- Get a new water pump with bolts and gaskets, an oil filter, an air filter, and a head gasket

- Either get the carburator cleaned professionally or do it myself

When everything is done, I'll get a torque wrench and rebuild the engine following the shop manual. I am still using RTA for the moment but I am trying to locate an used Haynes manual. I'll get a digital version of the Haynes later if necessary.

A summary of what I'm planning to do when the engine is back together:

- Fill the cooling system with distilled water and sodium bicarbonate and the oil reservoir with 50% Diesel and 50% Oil

- Run the car at idle until the fans come on as

@JdeW suggested

- Re-tighten the head bolts, flush the oil/Diesel mixture from the engine, change the oil filter and fill up with fresh Oil

- Drive ~500KM, flush the oil and the water/bicarb mixture, check the tightness of the bolts once again and fill up with a proper coolant mixture and good quality Oil

Feel free to point out any potential problem with this plan! I am somewhat concerned about cleaning the liners as I'm afraid to scratch them, but the carbon buildup is too much. Also, can the rockers be tuned while the head is off the engine? Can I clean the carb without messing it up by myself?