Sprackers

Enthusiast

- Messages

- 353

- Location

- Tunbridge Wells England

Hi all

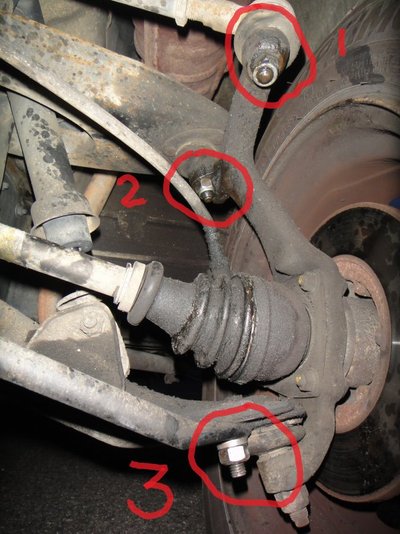

In preperation fopr my trip to Thenay via Stockholm I must address the CV Joint.

I have read all the threads and read my Haynes manuel and I still cant find a simple explanation how to do it.

Do I need a joist? or can I get away with just a couple of supports and a jack?

Do I need that special tool? I have a pretty good set of tools and plenty of common sense (or life skills as they call it now).

I have a microwave to replace the collar and I will need special grease.

ITs the nock nock as i turn left then quiet , so its def the CV joint.

Regards all

Sprackers

In preperation fopr my trip to Thenay via Stockholm I must address the CV Joint.

I have read all the threads and read my Haynes manuel and I still cant find a simple explanation how to do it.

Do I need a joist? or can I get away with just a couple of supports and a jack?

Do I need that special tool? I have a pretty good set of tools and plenty of common sense (or life skills as they call it now).

I have a microwave to replace the collar and I will need special grease.

ITs the nock nock as i turn left then quiet , so its def the CV joint.

Regards all

Sprackers