You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My renault 4 restoration

- Thread starter Domsky

- Start date

Domsky

Enthusiast

- Messages

- 128

- Location

- GLANWORTH republic of Ireland

Thanks for warm welcome.First a very warm welcome on this forum and thanks for showing your project so far. Does she need a lot of work? Keep us updated!

Well the chassis needs a lot of work , the body is in fairly good condition, i will be engine runs , but i will be rebuilding it anyway.

Domsky

Enthusiast

- Messages

- 128

- Location

- GLANWORTH republic of Ireland

the chassis is nearly ready to be blasted, i cant wait to have it completed and start to attach things to it , it would be great morale boostLove your videos! The start of episode 5 was a surprise. Can't wait to see the fresh floor welded in. Keep it up!

harbourseal

Renault R4 Lunatic

- Messages

- 1,049

- Location

- Breda The Netherlands

Nice project Good luck with it.

Domsky

Enthusiast

- Messages

- 128

- Location

- GLANWORTH republic of Ireland

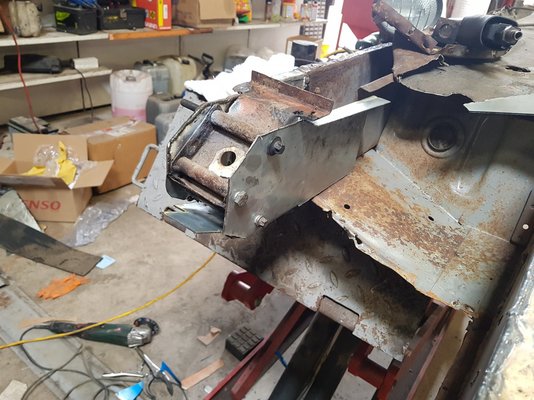

Some pictures from work

-

20180718_133458.jpg226.8 KB · Views: 15

20180718_133458.jpg226.8 KB · Views: 15 -

20180716_223136.jpg194.4 KB · Views: 16

20180716_223136.jpg194.4 KB · Views: 16 -

20180715_225050.jpg251.1 KB · Views: 14

20180715_225050.jpg251.1 KB · Views: 14 -

20180726_181438.jpg286.9 KB · Views: 16

20180726_181438.jpg286.9 KB · Views: 16 -

20180730_200110.jpg240 KB · Views: 16

20180730_200110.jpg240 KB · Views: 16 -

20180714_193905.jpg240.6 KB · Views: 15

20180714_193905.jpg240.6 KB · Views: 15 -

20180714_201604.jpg90.9 KB · Views: 18

20180714_201604.jpg90.9 KB · Views: 18 -

20180725_180954.jpg238.8 KB · Views: 16

20180725_180954.jpg238.8 KB · Views: 16 -

20180718_111931.jpg295.3 KB · Views: 18

20180718_111931.jpg295.3 KB · Views: 18 -

20180718_111917.jpg240.8 KB · Views: 13

20180718_111917.jpg240.8 KB · Views: 13

Domsky

Enthusiast

- Messages

- 128

- Location

- GLANWORTH republic of Ireland

Domsky

Enthusiast

- Messages

- 128

- Location

- GLANWORTH republic of Ireland

So now i have all the parts to have rolling chassis. And the chassis is nearly ready for blasting and priming , instead of stonechip underneath will be painted witch 2k bedliner , and all the cavities where the paint won't get will be treated with this top class wax .

-

20190205_101350.jpg117.7 KB · Views: 8

20190205_101350.jpg117.7 KB · Views: 8 -

20190205_101424.jpg124.2 KB · Views: 6

20190205_101424.jpg124.2 KB · Views: 6 -

20190205_101418.jpg108.9 KB · Views: 6

20190205_101418.jpg108.9 KB · Views: 6 -

15493621491013997622662987921157.jpg163.1 KB · Views: 9

15493621491013997622662987921157.jpg163.1 KB · Views: 9 -

15493622042835180906025000091007.jpg116.8 KB · Views: 9

15493622042835180906025000091007.jpg116.8 KB · Views: 9 -

15493622426293385830103789262169.jpg128.4 KB · Views: 10

15493622426293385830103789262169.jpg128.4 KB · Views: 10 -

15493622539284153116909959137601.jpg112.4 KB · Views: 10

15493622539284153116909959137601.jpg112.4 KB · Views: 10

JdeW

Enthusiast

- Messages

- 1,127

- Location

- Laarbeek The Netherlands

Very good work on the chassis  can't believe what I saw on that rear beam... pop rivets..how could someone....

can't believe what I saw on that rear beam... pop rivets..how could someone....

Nice to see the same rust spots and repairs especially on the front chassis beam(s) as I did.

Keep up the good work.

Best regards, Joop

can't believe what I saw on that rear beam... pop rivets..how could someone....

can't believe what I saw on that rear beam... pop rivets..how could someone....Nice to see the same rust spots and repairs especially on the front chassis beam(s) as I did.

Keep up the good work.

Best regards, Joop

Domsky

Enthusiast

- Messages

- 128

- Location

- GLANWORTH republic of Ireland

The poprivet job was acually nicely done , the previous owner had no access to the welderVery good work on the chassiscan't believe what I saw on that rear beam... pop rivets..how could someone....

Nice to see the same rust spots and repairs especially on the front chassis beam(s) as I did.

Keep up the good work.

Best regards, Joop

JdeW

Enthusiast

- Messages

- 1,127

- Location

- Laarbeek The Netherlands

I know airplanes do have a lot pop riveting and it is strong, but in our country due to car MOT regulations, a pop rivet job is not allowed on chassis structural parts,it has to be welded.The poprivet job was acually nicely done , the previous owner had no access to the welder

That's why I was a bit surprised.

Domsky

Enthusiast

- Messages

- 128

- Location

- GLANWORTH republic of Ireland

The repairs were done in the 90s in poland , where you could get test for extra 50 in the ashtrayI know airplanes do have a lot pop riveting and it is strong, but in our country due to car MOT regulations, a pop rivet job is not allowed on chassis structural parts,it has to be welded.

That's why I was a bit surprised.

Domsky

Enthusiast

- Messages

- 128

- Location

- GLANWORTH republic of Ireland

, Welcome along!

, Welcome along!