Snoopy1974

Enthusiast

- Messages

- 412

The engine was not perfectly horizontaly hanged, so it was a little difficult to put it easily in the chassis:

But after few minutes of maxi stress the engine was finally fitted in the chassis

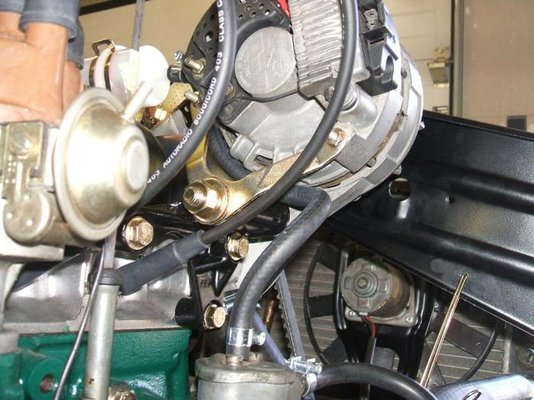

I decided to fit the water pump, to be sure that it will be water tight I decided to put the Loctite product on each side of the Renault seal, first on the water pump:

Then, on the seal after applying it on the water pump:

I don't have torque spanner, so when I fitted the water pump on the cylinder head I took care not to tighten the bolts too much:

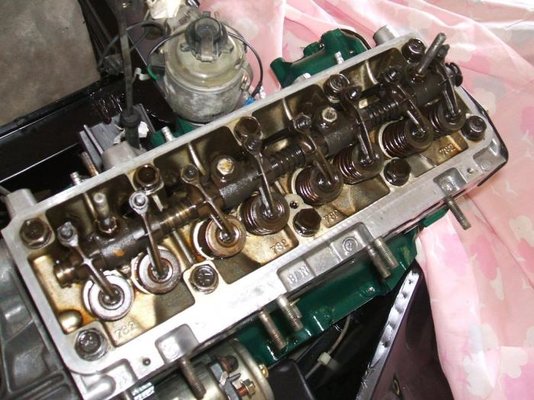

Just a little picture of my rocker levers before fitting the valve cover, the manifold was fitted just after:

The valve cover was fitted with the fuel filter bracket:

It's late and I have to get up at 6, I think it will be VERY difficult

The continuing of my story will be written later, good night

The continuing of my story will be written later, good night

I'm gonna try to do such a good job on the body but it won't be easy, there are many, many damaged parts... much more than I expected

I'm gonna try to do such a good job on the body but it won't be easy, there are many, many damaged parts... much more than I expected