Rutger-peer

The restoring Dutchman.

- Messages

- 260

Haha, well, I'd rather have them produced in Germany too! Here in the Netherlands we even say "Duitse degelijkheid", which would translate into something like "German reliability". The Germans themselves call it "Deutsche Grunlichkeit". Well anyway, I guess I am taking this too far.

I got a question for you actually:

How did you paint the wishbones and other (strangely shaped) parts of the suspension? I see you left some on your chassis and painted it with the chassis but what about the wishbones etc.?

I have been cleaning them with a wirebrush but can't get into all the small corners etc. Did you paint them with special paint? Do you think spraypaint would do the job (from a spraycan)?

I got a question for you actually:

How did you paint the wishbones and other (strangely shaped) parts of the suspension? I see you left some on your chassis and painted it with the chassis but what about the wishbones etc.?

I have been cleaning them with a wirebrush but can't get into all the small corners etc. Did you paint them with special paint? Do you think spraypaint would do the job (from a spraycan)?

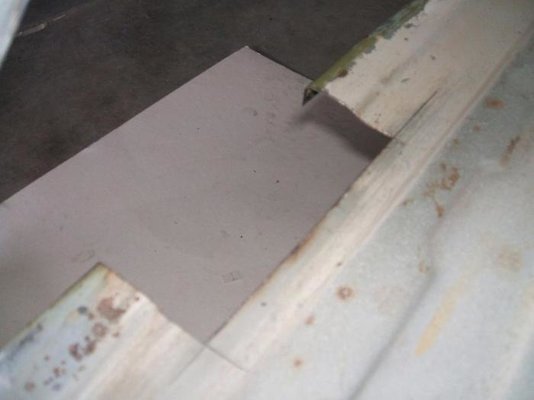

The right rear wing support seems to be curiously in a very good condition, rust is present but only at the surface of this part

The right rear wing support seems to be curiously in a very good condition, rust is present but only at the surface of this part

) of the column, I have to remove this "clip". Every time I remove such a part, I fear to take it in my face :eek:

) of the column, I have to remove this "clip". Every time I remove such a part, I fear to take it in my face :eek:

. Hope somebody else will be able to tell you that. Is it not stretchy, so it will stretch over the thicker part?

. Hope somebody else will be able to tell you that. Is it not stretchy, so it will stretch over the thicker part?