malcolm

& Clementine the Cat

- Messages

- 4,635

- Location

- Bedford UK

I got around to removing the cylinder head from the Gordini this afternoon. I hadn't got around to doing a compression check, but identified a problem with the distributor that might have explained some of the running problems.

Further issues were the bong bong noise at idle similar to this thread http://www.renault4.co.uk/forum/showthread.php?t=3527 and of course all the water that made it's way into the oil during the Kent run.

I'll go about the head gasket first. The bong bong noise is most likely the timing chain, but I don't want to tackle them both at the same time as I'll never be sure it definitely is the timing chain bonging, and I have another car in the yard making the same noise so would like to be completely sure.

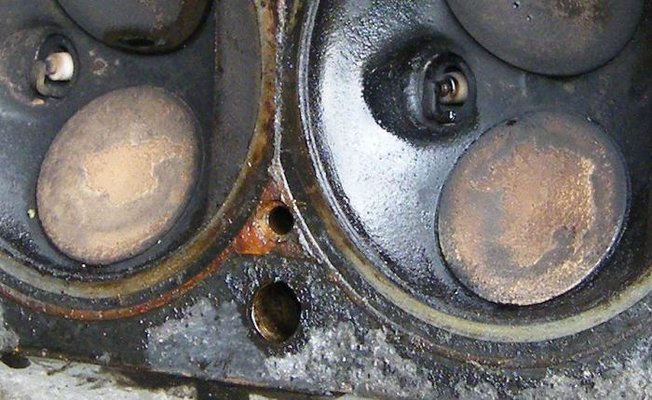

Some pictures for now.

There's definitely some water in the oil. Nasty scum:

The head has been removed in the past - but not recently as the gasket has had time to go a bit nasty. Some discolouration there amongst other things.

Somebody seems to have honed the bores at some point. I hope they took precautions with the liner seals.

If anyone spots anything I haven't do shout. The last MOT for that engine was in 1999, but I have no history. The head does need a skim even judging from my not very straight edge, but the liner height looks good.

More later.

Further issues were the bong bong noise at idle similar to this thread http://www.renault4.co.uk/forum/showthread.php?t=3527 and of course all the water that made it's way into the oil during the Kent run.

I'll go about the head gasket first. The bong bong noise is most likely the timing chain, but I don't want to tackle them both at the same time as I'll never be sure it definitely is the timing chain bonging, and I have another car in the yard making the same noise so would like to be completely sure.

Some pictures for now.

There's definitely some water in the oil. Nasty scum:

The head has been removed in the past - but not recently as the gasket has had time to go a bit nasty. Some discolouration there amongst other things.

Somebody seems to have honed the bores at some point. I hope they took precautions with the liner seals.

If anyone spots anything I haven't do shout. The last MOT for that engine was in 1999, but I have no history. The head does need a skim even judging from my not very straight edge, but the liner height looks good.

More later.

!!

!!