You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

R4 TL restauration

- Thread starter Jurjenz

- Start date

Jurjenz

Enthusiast

- Messages

- 468

- Location

- Groningen, Netherlands

Snoopy1974

Enthusiast

- Messages

- 412

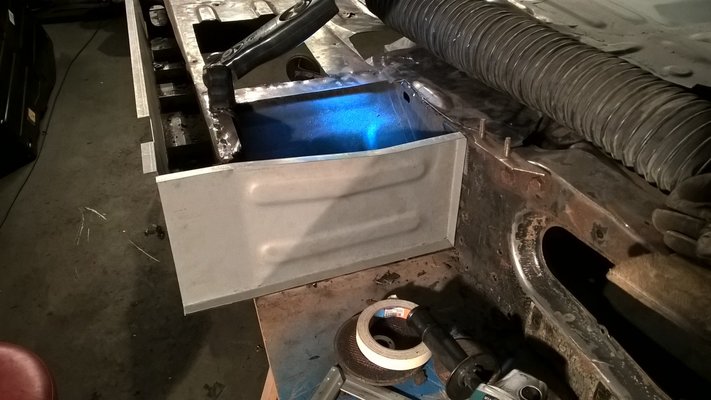

Congratulations, you really did an awesome job on your chassis

Your primer looks like the same which is used by many R4 owners in France, and called Rustol CIP:

http://owatrol.com/marine/metal/primaire/10414-owatrol-cip.html

Your primer looks like the same which is used by many R4 owners in France, and called Rustol CIP:

http://owatrol.com/marine/metal/primaire/10414-owatrol-cip.html

Jurjenz

Enthusiast

- Messages

- 468

- Location

- Groningen, Netherlands

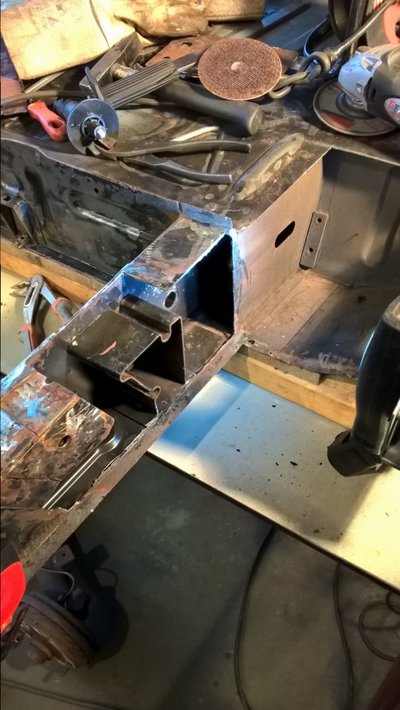

Noooo troubles!

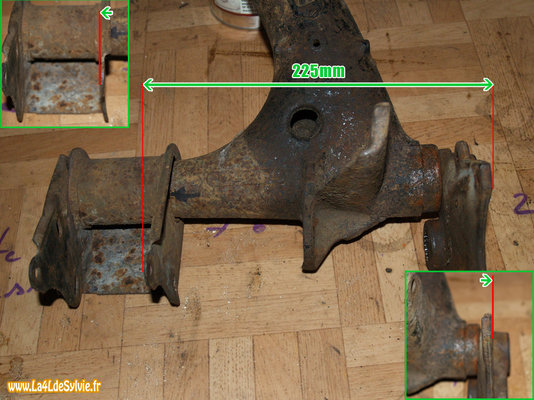

Noooo troubles!Today I was working on the rear axle. I did some cleaning with a steel wire brush and I decided - before going on further cleaning - to remove the silent blocks on both sides. It was a dirty job but I managed. When cleaning the inner tubbes it seems rust had made some holes, bummer!!!

I think this is beyond repair? What do you advice?

Last edited:

mr-reno-139

AKA Paul Cunningham

- Messages

- 2,279

- Location

- lancing west sussex england

If everyone stripped their rear axles this far I expect this would be a common sight

No way of knowing how bad they are until they snap normally

Have known people get a steel tube fabricated and sleeve internally

No way of knowing how bad they are until they snap normally

Have known people get a steel tube fabricated and sleeve internally

Jurjenz

Enthusiast

- Messages

- 468

- Location

- Groningen, Netherlands

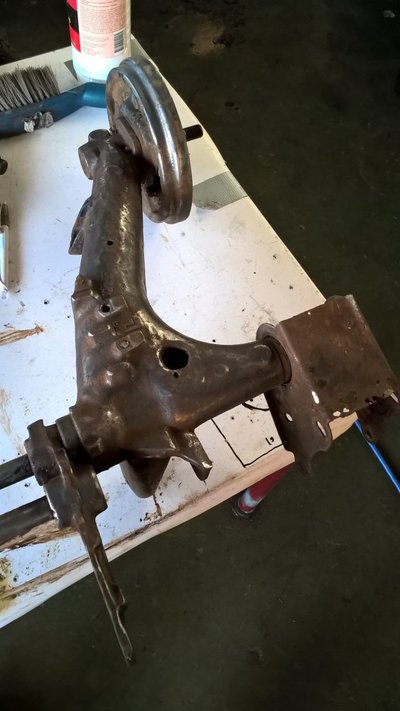

Yeeeey I got a new rear axle. Some time ago it was restored (sandblasted etc.) but the owner got ill and the axle was set alone in storage.. I'm happy I got it! I'm doubting if I will replace the silent blocks, they seem on pretty good condition..

Yeeeey I got a new rear axle. Some time ago it was restored (sandblasted etc.) but the owner got ill and the axle was set alone in storage.. I'm happy I got it! I'm doubting if I will replace the silent blocks, they seem on pretty good condition..What is an easy way to line up new silent blocks? I think most easy (before removing the old ones) is to measure the distance between silent blocks (axle lying flat) and the floor. We also got a 'new' compressor, as old as I'm - hehehe - and still working fine! I can now sandblast the way it should be..

Last edited:

Paul Narramore

pre-moderated

- Messages

- 840

- Location

- Aylesford, Kent

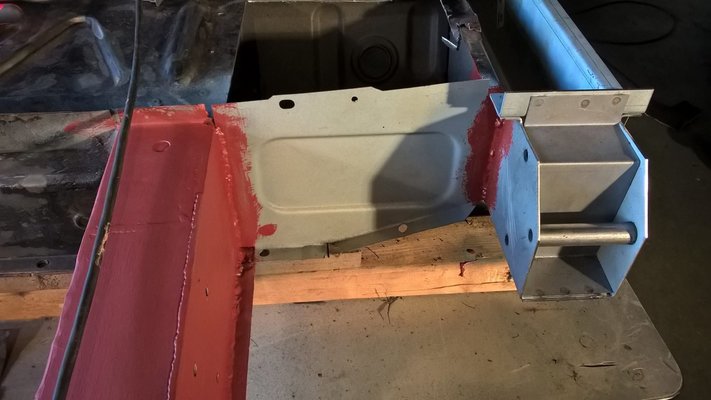

Wow, I just love seeing this sort of thorough restoration in pictures. Tell me, when you've finished the chassis, presumably you'll be injecting something like Waxoyl into the chassis so that it lasts for years? Are there already holes in the chassis for this? When you weld in a new plate, how do you decide whether you butt weld the edges or plug weld them? Once you've spot welded a plate in, do you then follow up with a continuous weld or do you think that is unecessary? Excellent job! :-D

Paul,

I can't help you with any tips on welding. Others may be able to finesse the advantages of butt vs plug welding.

On the other hand, now that the body is removed from the chassis you will find around 23 captive nuts in the chassis where the body bolts to it. I reckon that will give enough access to pour in whatever brand of alchemy you can brew!

Fish (fish oil) vs Lamb (lanolin) vs proprietary concoctions (waxoyl). I've heard of people using used ATF as it's cheap and quite "wicky"

Ultimately, you have to decide what rust preventative technique you use.

It is imperative that you do some research into what people use (and are happy with) in your country when treating the SAME vehicle. (R4)

There are other access areas that will be revealed with any cut to repair rusted metal.

David

I can't help you with any tips on welding. Others may be able to finesse the advantages of butt vs plug welding.

On the other hand, now that the body is removed from the chassis you will find around 23 captive nuts in the chassis where the body bolts to it. I reckon that will give enough access to pour in whatever brand of alchemy you can brew!

Fish (fish oil) vs Lamb (lanolin) vs proprietary concoctions (waxoyl). I've heard of people using used ATF as it's cheap and quite "wicky"

Ultimately, you have to decide what rust preventative technique you use.

It is imperative that you do some research into what people use (and are happy with) in your country when treating the SAME vehicle. (R4)

There are other access areas that will be revealed with any cut to repair rusted metal.

David

mr-reno-139

AKA Paul Cunningham

- Messages

- 2,279

- Location

- lancing west sussex england

http://www.renault4.co.uk/forum/threads/rodeo-5-encouragement-needed.7063/I had great fun filling my chassis with waxoyl using a garden sprayer

Loads of pics of my chassis on my restoration post

Welcome to come and have a look and make me feel guilty for not getting on with it

Loads of pics of my chassis on my restoration post

Welcome to come and have a look and make me feel guilty for not getting on with it

Paul Narramore

pre-moderated

- Messages

- 840

- Location

- Aylesford, Kent

Jurgenz, What are you going to paint the suspension with? Are you familiar with POR15? Sold by Frost's, it dries to a rock hard gloss but once the lid has been levered open, the paint must be used up. By next day, you will destroy the can trying to get the lid open and the paint will have set. Use disposable brushes too ;-)

Paul Narramore

pre-moderated

- Messages

- 840

- Location

- Aylesford, Kent

I don't know that brand, thanks for the advise! I bought epifanes 2K paint, hope that wil work too.

Jurjenz, Have a look at www.frost.co.uk They are lots and lots of paints, etc, for car restorers. I painted the suspension of my Lomax 223 in light grey POR15 and it came up like glass. I bought a box of very small tins as I could throw each away after I had used them. They won't keep for a second day.

PS How I envy you your grit blasting cabinet.