You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

R4 TL restauration

- Thread starter Jurjenz

- Start date

JonathanT

Not normal for Norfolk

- Messages

- 1,335

- Location

- Wymondham Norfolk

Great to see your amazing workshop. All being together like that means you can help each other out and it must be great for motivation tooNew update

Short walkaround on our workshop:

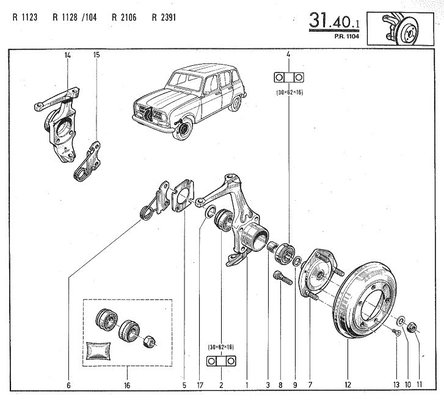

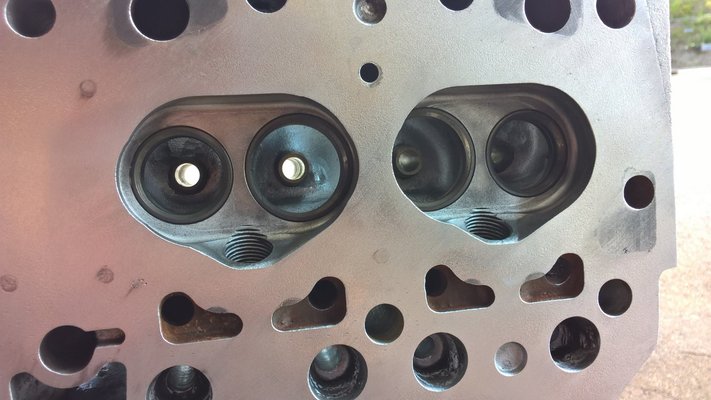

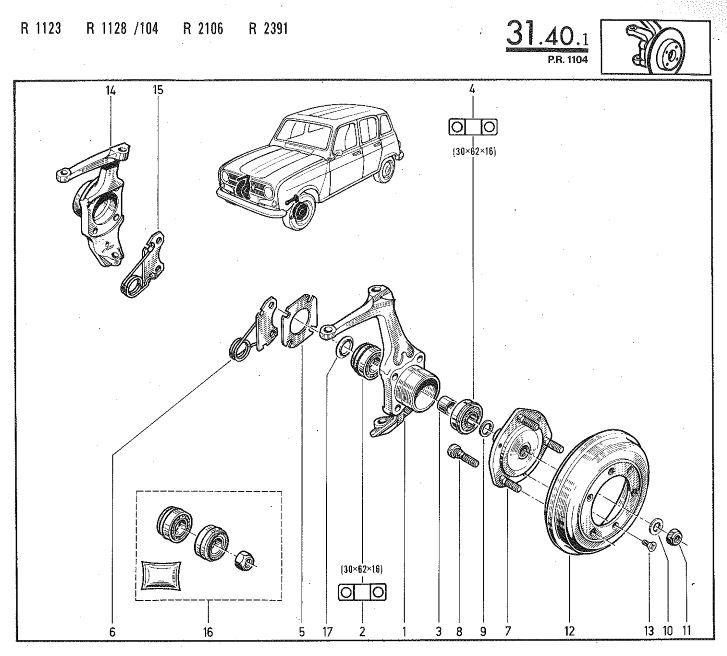

I ordered new bearings as the ones shown below are old and noisy. In what order do I need to put the parts together?

- 2 into 1

- 4 into 1

- 7 into 4

?

mr-reno-139

AKA Paul Cunningham

- Messages

- 2,279

- Location

- lancing west sussex england

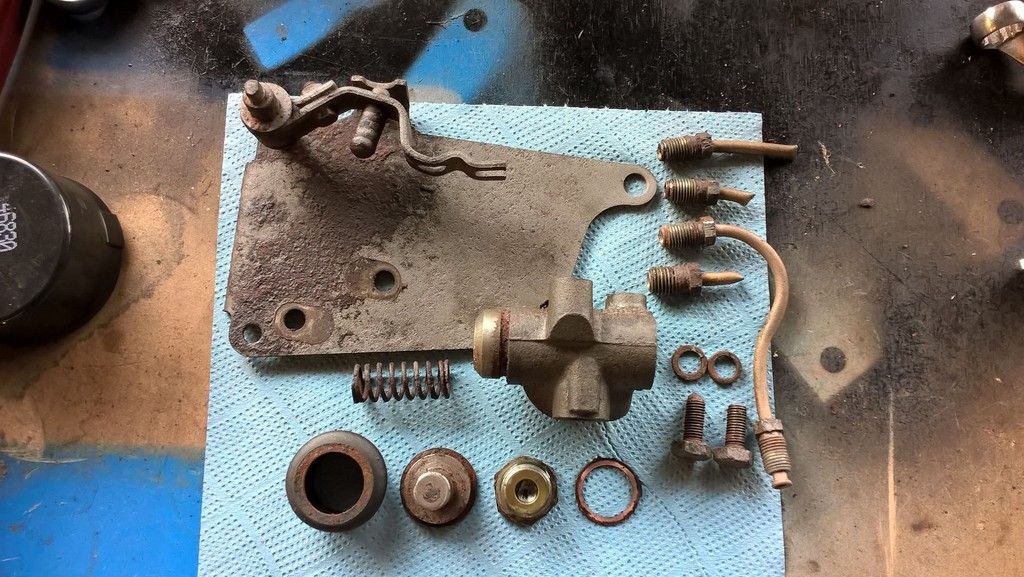

The part you need for gearbox I should have one on the top case that I will be using for my rodeo as once I bolt it to the 5 speed box pretty sure acording yo what i've read I have to fit the 5 ha 1 selector arm

Can post if nothing closer turns up

Can post if nothing closer turns up

mr-reno-139

AKA Paul Cunningham

- Messages

- 2,279

- Location

- lancing west sussex england

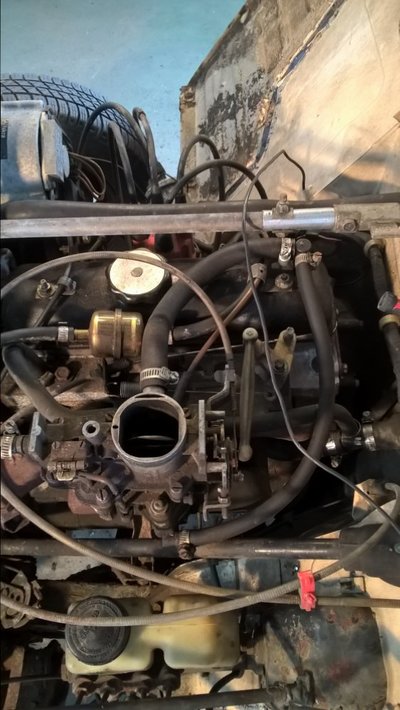

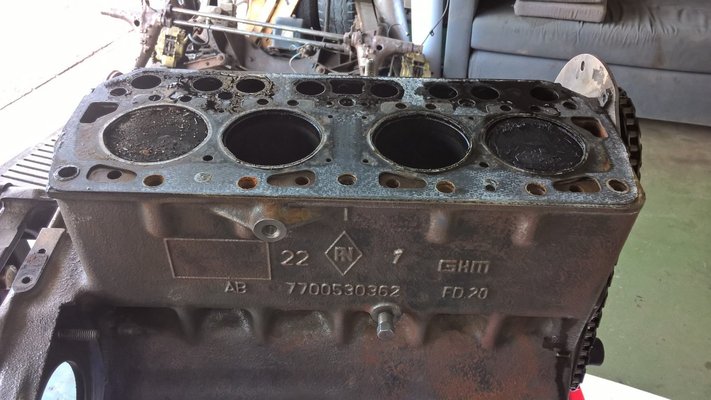

It's a ventoux engine 3 bearing runs opposite direction 845cc

More popular overseas than uk as after 79 nearly all uk cars and vans 1108 cc

More popular overseas than uk as after 79 nearly all uk cars and vans 1108 cc

harbourseal

Renault R4 Lunatic

- Messages

- 1,049

- Location

- Breda The Netherlands

It runs anti-clockwise, but the dizzy runs clockwise. No trouble reconnecting the spark plug leads. 1342 beginning with the one closest to the alternator counting from the flywheel.

mr-reno-139

AKA Paul Cunningham

- Messages

- 2,279

- Location

- lancing west sussex england

Paul Narramore

pre-moderated

- Messages

- 840

- Location

- Aylesford, Kent

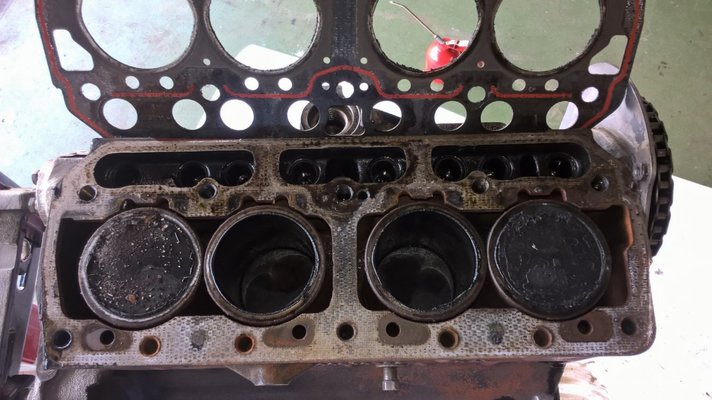

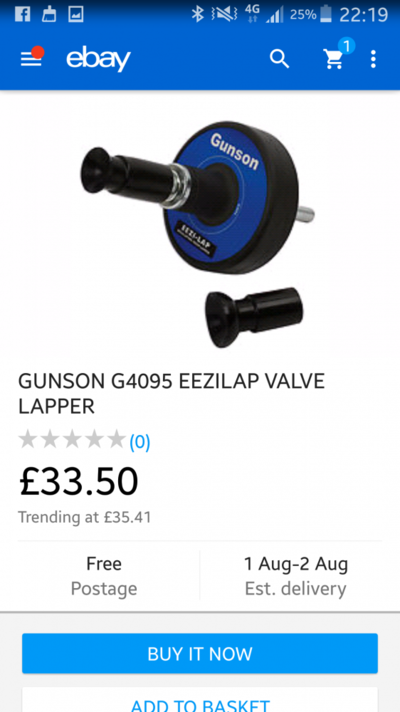

Yes, as using a drill would simply spin the valve in one direction only.

mr-reno-139

AKA Paul Cunningham

- Messages

- 2,279

- Location

- lancing west sussex england

The tool I use also attached to electric drill but creates back and forth motion

Jurjenz

Enthusiast

- Messages

- 468

- Location

- Groningen, Netherlands

Thanks for that tool! Seems like it is very useful.

EDIT

Found this comment on a youtubevideo which also used a drill. Makes sense, learnful lesson for the next time:

ER You should NEVER rotary lap a valve in esp with a drill, it HAS to be a BACK AND FORTH action then LIFT OFF the seat to reset the valve paste on the seat, (as the paste grinding sound goes quieter usually 4 or 5 times ) then turn the valve a few degrees and then rept motion. like starting a fire but if you rotate it, you burn scars into the seat,, meaning the valve seat gets hotter and clogs with carbon deposits in these scars, which then burns the seat again meaning another head rebuild. And you start the VALVE Grinding with COARSE paste, then clean off and move to a SMOOTH grinding paste for a nice consistent groove free flat greyish looking seat ! The best way to check if it has worked is to use a soft pencil like a HB and scribe three vertical lines at 120 degrees apart on the seat when you refit the valve on the seat twist the valve when in contact with the seat and the 3 pencil marks will rub evenly along the seat, if not then the seats need regrinding again or you need new valves and or valve guides.,

This is for the lazy mechanics. EAZILAP by GUNSONS, been here 40 odd years, a DRILL ADAPTER, which oscillates back and forth ( ) http://www.ebay.co.uk/itm/Gunson-G4...nds-Grinder-22-28mm-Sucker-Head-/310719942809

EDIT

Found this comment on a youtubevideo which also used a drill. Makes sense, learnful lesson for the next time:

ER You should NEVER rotary lap a valve in esp with a drill, it HAS to be a BACK AND FORTH action then LIFT OFF the seat to reset the valve paste on the seat, (as the paste grinding sound goes quieter usually 4 or 5 times ) then turn the valve a few degrees and then rept motion. like starting a fire but if you rotate it, you burn scars into the seat,, meaning the valve seat gets hotter and clogs with carbon deposits in these scars, which then burns the seat again meaning another head rebuild. And you start the VALVE Grinding with COARSE paste, then clean off and move to a SMOOTH grinding paste for a nice consistent groove free flat greyish looking seat ! The best way to check if it has worked is to use a soft pencil like a HB and scribe three vertical lines at 120 degrees apart on the seat when you refit the valve on the seat twist the valve when in contact with the seat and the 3 pencil marks will rub evenly along the seat, if not then the seats need regrinding again or you need new valves and or valve guides.,

This is for the lazy mechanics. EAZILAP by GUNSONS, been here 40 odd years, a DRILL ADAPTER, which oscillates back and forth ( ) http://www.ebay.co.uk/itm/Gunson-G4...nds-Grinder-22-28mm-Sucker-Head-/310719942809